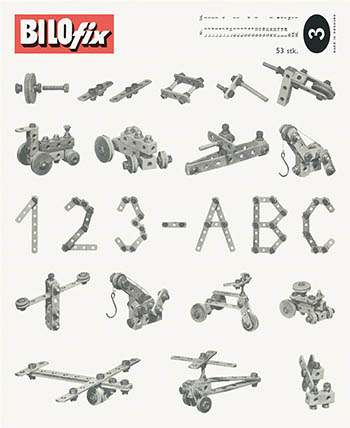

In the 1930s Ole Kirk Christiansen, Lego’s founder, began making wooden toys just to survive the depression. After the war he bought the first injection molding machine in Denmark and began making plastic toys. These early plastic toys – including the first Lego bricks – were no match for the quality of their wooden toys, but Ole’s son Godtfred, now Lego’s managing director, felt that the Lego brick and his System of Play was the future of the company.

He turned out to be right: sales of wooden toys peaked in 1952 and by the late 1950s the System of Play was responsable for more than twice the revenue of the wooden toys so in 1959 Godfred decided to split the company in two: the plastic bricks were sold under the name Lego and the wooden toys were rebranded under the name BILOfix.

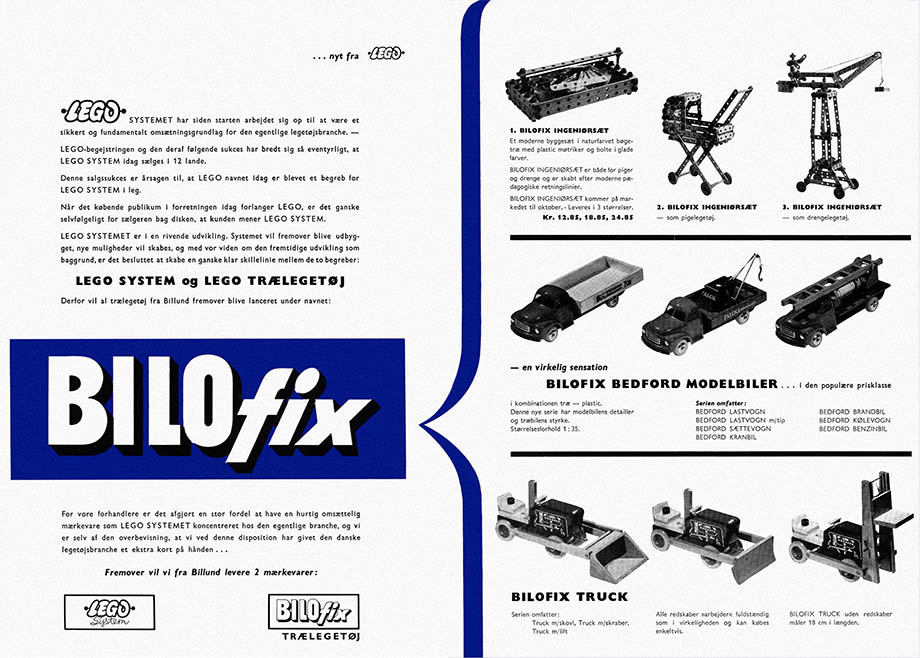

Lego selvbinder as a Lego toy (1954) and as a BILOfix toy (1959)

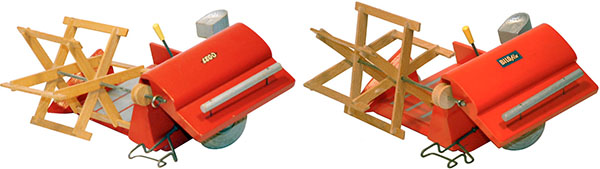

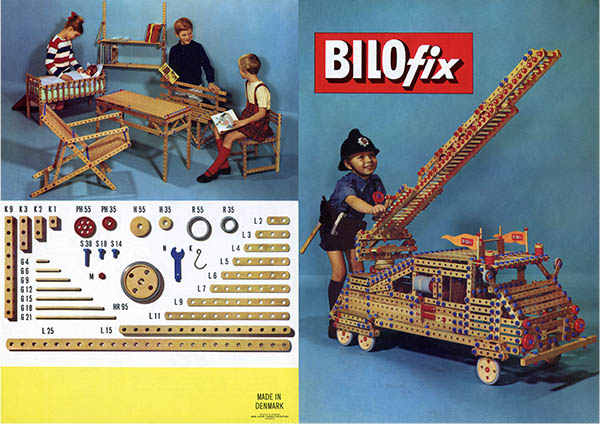

BILOfix transport truck, 1959

The new BILOfix division wasn’t long for the world. On 4 Feb 1960 the Lego warehouse in Billund, Denmark burned to the ground, destroying their entire inventory of wooden toys. Godtfred reassessed the business and decided to compete with the flood of post-war American and Japanese mass-produced toys with own mass-produced toy: the Lego System. There would be no more labor-intensive wooden toys – just the Lego System. This eggs-all-in-one-basket approach was a radical idea and his brothers argued against it. They argued so vehemently that Godtfred eventually bought out their interests in the company.

Godtfred’s younger brother Gerhardt, who had run Lego’s wood toy division, was especially upset. He moved to nearby Kolding and began his own toy company, taking Lego’s woodworking tools and the name BILOfix with him.

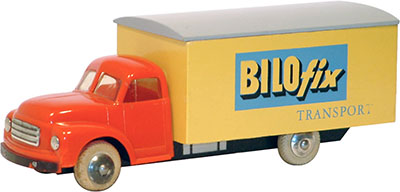

Gerhardt’s BILOfix system was a construction toy based on wooden blocks and beams connected by plastic nuts and bolts. It was no ordinary run-of-the-mill toy however, Gerhardt had applied every lesson he learned from the family company: it was made of kiln-dried furniture-grade birch and expensive molded ABS plastic; 1 it was modular and expandable; it was marketed in large sets and small supplementary boxes and included ideas for an unlimited number of models. In other words it was going to be the toy that Gerhardt though Godtfred should be making. It was going to be Gerhardt’s Lego-killer.

1963 Danish catalog

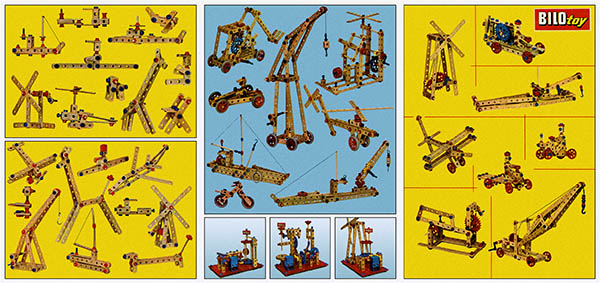

BILOfix became popular in educational circles and soon sales began to grow. Gerhardt expanded his factory and eventually employed more than 100 people. At its peak in the mid-1960s he was producing 40,000 blocks and 150,000 beams a day and was processing three truckloads of wood a week. The toy even won awards in France (the Meilleur Jouet) and Denmark (the Jeppe)

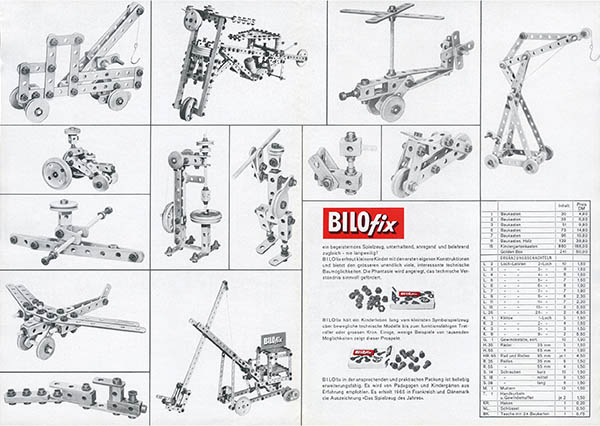

1966 German catalog

By the late 1960s BILOfix was sold in much of Europe, but the company was too small to attempt more widespread distribution (a problem his brother at Lego was grappling with as well) so Gerhardt contracted with the American company Revell (the plastic model kit company) to market the system internationally. Revell renamed the system BILOtoy and even had Gerhardt design new parts and sets.

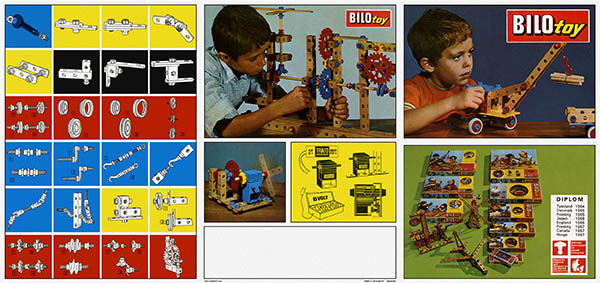

1968 Danish catalog

To Gerhardt BILOtoy was his life but to Revell it was just one of many toys they marketed. It soon became clear that the very expensive educational BILOtoy was not their priority and in 1972 they dropped the line stating that “high price increases from the Danish manufacturer would not be acceptable...”

The result was catastrophic for Gerhardt: he was left with a warehouse full of unsold inventory and had to sell his factory and lay off much of his staff. Gerhardt spent the rest of the decade trying to find new distributors but ultimately couldn’t compete with the rise of electronics and video games. He sold the company in 1980.2

After 1980 the toy went through various owners, none of whom shared Gerhardt’s insistance on quality, and is now no longer manufactured. Gerhardt’s Lego-killing idea has become a footnote in toy history. Godtfred’s Lego, on the other hand, eventually solved its distribution problems and is now the largest toy company in the world.

1. The wood for Bilofix was supplied by the Ferrer ritslev sawmill from nearby Funen. In a 1967 interview Gerhardt claimed that he only used “the top 40 percent of straight-grained, knot-free mature [silver] birch.” The plastic elements were made by Gerhardt’s brother Karl George at his injection-molding company in Kolding. The toy was so durable that it actually discouraged repeat sales; it was simply handed down through the family.

2. Interestingly at the same time Gerhardt was starting BILOfix he was also starting a toy retailer in central Denmark under the name GK Legetøj, eventually having nine stores. The mini-chain was taken over by his son Mogens and renamed Buddy Legetøj. Despite competition from big-box retailers and the Internet Buddy Legetøj is still in business. And, yes, Buddy sells Lego.

22 Sep 2015 ‧ Design